Precision manufacturing, tailored to your needs! Our CNC full custom machining service provides a one-stop solution for customers in industries such as mechanical manufacturing, mold development, 3C electronics, automotive components, and medical devices, covering everything from product design and process planning to precision machining and surface finishing. Leveraging multi-axis CNC equipment, a professional technical team, and a strict quality control system, we can meet full-scenario demands from single-piece prototyping to mass production, helping customers quickly turn ideas into high-quality physical products.

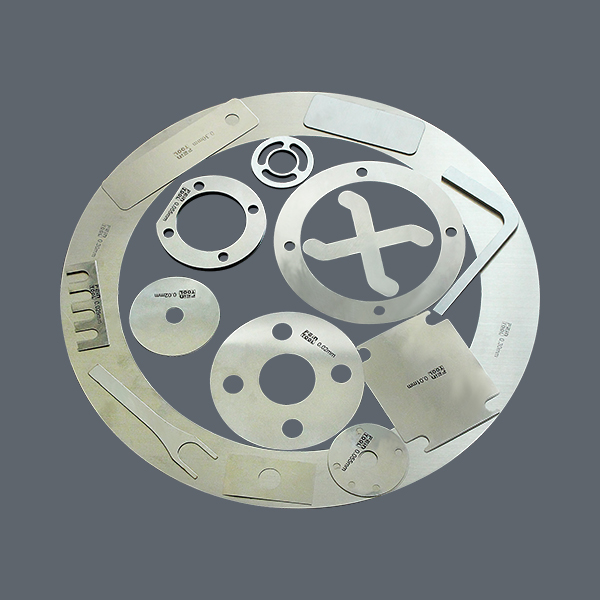

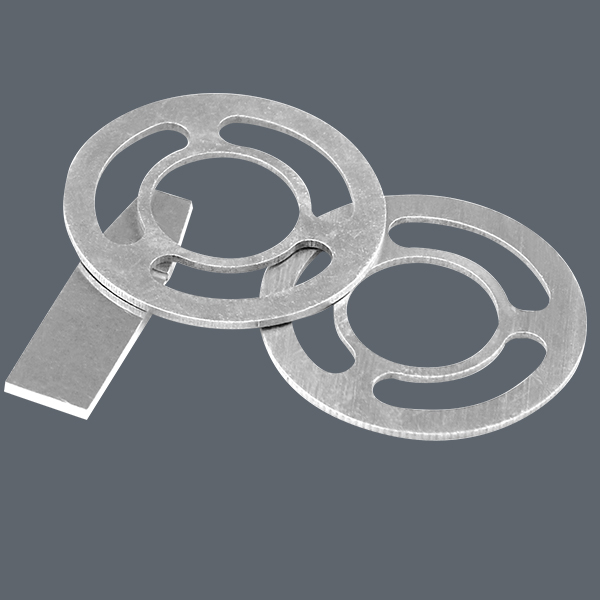

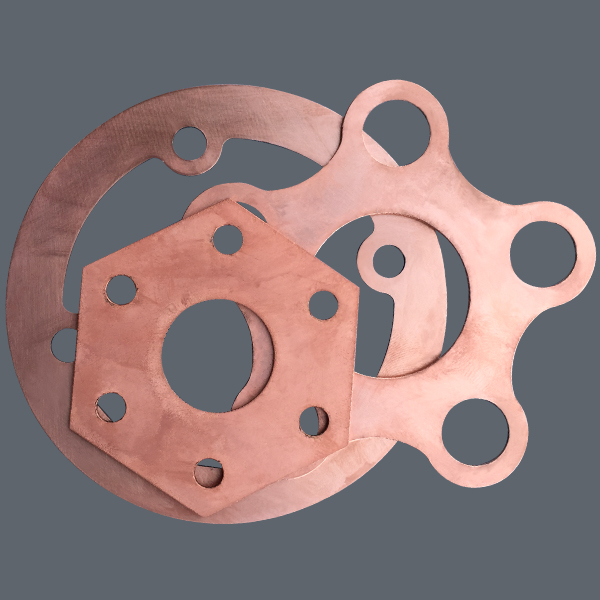

We maintain a comprehensive CNC equipment portfolio, including 5-axis machining centers, high-speed drilling and tapping machines, precision grinders, and wire EDM cutters. This allows us to efficiently process a wide range of materials, such as aluminum alloy, stainless steel, titanium alloy, and engineering plastics, and achieve ultra-high-difficulty features like complex curved surfaces, micro-holes, and precision threads. Tolerance accuracy is stably controlled within ±0.005mm, meeting the extreme precision requirements of aerospace, medical devices, and other high-end fields.

Core service advantages to fully guarantee delivery quality:

- Full-link technical support: From early-stage DFM (Design for Manufacturability) analysis and structural optimization suggestions, to mid-stage process planning and machining parameter debugging, and late-stage inspection reports and after-sales technical support, we provide end-to-end professional services. This reduces trial-and-error costs and shortens project cycles.

- Flexible production with rapid response: We support small-batch, multi-variety orders, equipped with an intelligent production scheduling system. Regular prototyping orders can be delivered in as fast as 24 hours, and mass production orders can be initiated within 72 hours, meeting customers’ urgent R&D and market delivery needs.

- Strict quality control system: We have introduced high-precision testing equipment including CMM (Coordinate Measuring Machines), metallographic microscopes, and roughness testers. We implement a three-level quality control standard of “first-piece full inspection, in-process patrol inspection, and final finished product inspection”, ensuring every product meets drawing requirements with fully traceable quality.

- Comprehensive value-added process support: In addition to CNC machining, we offer supporting surface treatment processes such as anodizing, hard anodizing, sandblasting, passivation, and laser marking, as well as secondary finishing services like tapping, chamfering, and deburring. This achieves “one order, finished product delivery”.

User-friendly service details to meet diverse needs:

- Dedicated project manager: Each order is assigned a dedicated project manager who provides real-time production progress updates, responds promptly to process adjustments and demand changes, ensuring efficient and smooth communication.

- File compatibility and confidentiality: We support multiple drawing formats including STEP, IGS, and CAD, and strictly enforce confidentiality agreements for customer drawings and technical data. Exclusive confidentiality contracts are signed to protect intellectual property security.

- Material procurement and traceability: We provide procurement services for mainstream machining materials and can issue material certificates, ensuring material quality and compliance, and eliminating customer procurement concerns.

Widely applicable across industries: Whether it’s prototype validation for innovative enterprises, experimental part processing for research institutions, batch part supporting for manufacturing enterprises, or precision component manufacturing for medical devices, our CNC full custom machining service can accurately match your needs. With core capabilities of high precision, fast delivery, and strong service, we become a reliable technical partner for customers, helping products quickly launch and iterate in the market!

评价

目前还没有评价