Precision clamping, stable spindle control! This CNC high-precision ER clamping nut is a core fastening component specially matched with ER spring collets, designed for the spindle fixture systems of CNC machining centers, engraving machines, milling machines, drilling and tapping machines and other numerical control equipment. With its precision taper fitting technology, high-strength material craftsmanship and user-friendly structural design, it provides uniform and stable clamping force for collets, fundamentally ensuring tool holding accuracy and eliminating issues like runout, loosening and tool dropping during high-speed cutting. It is a key accessory for high-precision operations including mold processing, precision part manufacturing and 3C electronic component machining, helping improve processing quality and production efficiency.

Forged from premium chromium-molybdenum steel (Cr-Mo) via precision forging—far superior to ordinary carbon steel—the nut undergoes triple processing: high-temperature quenching, low-temperature tempering and precision grinding. Boasting a hardness rating of HRC 50-55, it delivers exceptional torsional strength and impact toughness. Even under high-speed cutting conditions of tens of thousands of RPM, it can withstand continuous clamping stress and centrifugal force impact without deformation, thread slipping or cracking. It maintains stable performance even after long-term, high-frequency tool changes and clamping, with a service life 4-6 times longer than standard nuts. The surface features dual treatment: nickel plating for rust resistance + mirror polishing, which not only resists long-term erosion from cutting fluids and oil stains to prevent rust and jamming, but also reduces friction resistance during tightening for smoother, more labor-saving clamping operations.

Core structural designs target key CNC machining pain points:

- Ultra-precision taper and thread machining: The taper surface is finished by 5-axis precision grinding, achieving over 98% fit with ER spring collets. When tightened, clamping force is evenly transmitted to the collet slots, avoiding collet eccentricity caused by uneven force distribution. This ensures the tool’s total indicator runout (TIR) is stably maintained within the ultra-high precision range of 0.003mm-0.01mm. The internal threads are manufactured via precision fine-thread rolling, reaching grade 6H precision with minimal fit clearance with spindle tool holders and collets. No loosening gap remains after clamping, guaranteeing stable concentricity during spindle rotation.

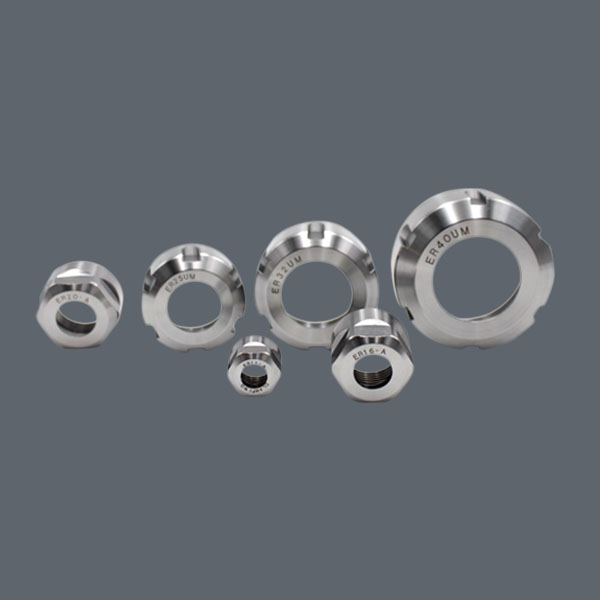

- Dual anti-slip and anti-loosening protection: The outer surface adopts a dual force-bearing structure of knurled anti-slip texture plus hexagonal/octagonal shape, compatible with dedicated wrenches. It provides a secure grip without slipping even during operation in wet, oily environments with splashing cutting fluids. Premium models are equipped with built-in anti-loosening washers or adopt anti-loosening thread designs, effectively counteracting vibrations generated by high-speed rotation, preventing nut loosening and completely eliminating the risk of tool dropping for safer machining.

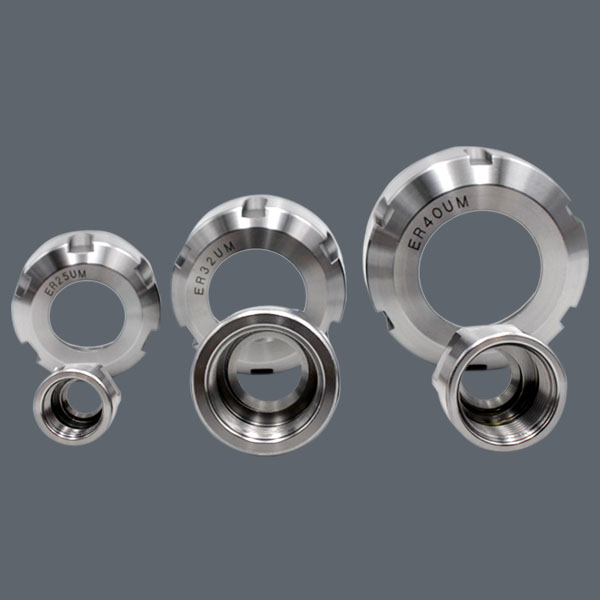

- Efficient heat dissipation and chip removal design: Annular heat dissipation grooves are added to the nut end face, quickly dissipating heat generated during cutting to avoid nut deformation or collet elasticity attenuation caused by high temperatures. The grooves also function as chip removal channels, preventing cutting chips from entering the fit clearance between the nut and collet, avoiding jamming or precision loss and extending the overall service life of both the nut and collet.

Standardized design and user-friendly details meet diverse needs:

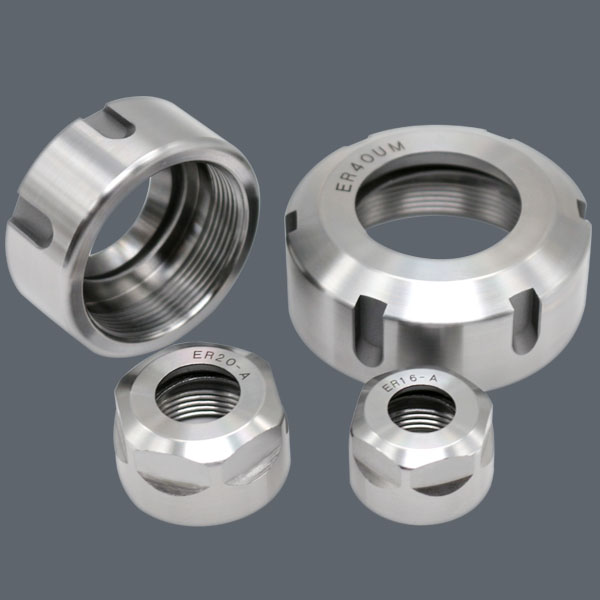

- Full coverage of specifications and models: Strictly compliant with international ER standards, nut models correspond one-to-one with ER collets, covering the complete range from ER8 to ER32. Compatible with matching collets and CNC spindles, installation and disassembly require no additional debugging for exceptional versatility. It meets clamping needs for tools ranging from 0.5mm micro cutters to 32mm heavy-duty cutters.

- Lightweight balance design: The internal structure is optimized to reduce weight while maintaining strength, with precise dynamic balance calibration. This minimizes centrifugal force during high-speed rotation, reducing spindle vibration and further improving machining accuracy and workpiece surface finish.

- Clear specification marking: Each nut end face is clearly engraved with its model and specification for quick identification and access in workshops. Paired with a classified storage case, it simplifies management, significantly reduces tool change time and boosts production efficiency.

Widely applicable in professional scenarios: Whether it’s high-speed mold cavity milling in die shops, drilling and tapping of hardware parts in precision machinery factories, micro-component engraving in 3C electronics plants or fine wood and acrylic cutting on engraving machines, this high-precision ER clamping nut pairs perfectly with ER collets for stable performance. With core advantages of ultra-high precision, strong clamping force, wear resistance and long service life, it becomes a reliable partner for CNC machining fixture systems, ensuring accurate and efficient cutting operations every time and helping enterprises stably produce high-quality products!

评价

目前还没有评价